Cat 3604 Generator Manual

Need a wiring diagram for a 1984 dometic dtxp55 4500watt. The snow blower start on off position and want stop. I need a manual for a Troy bilt edgercultivator 841010339.

INSTANT DOWNLOAD (add to cart)

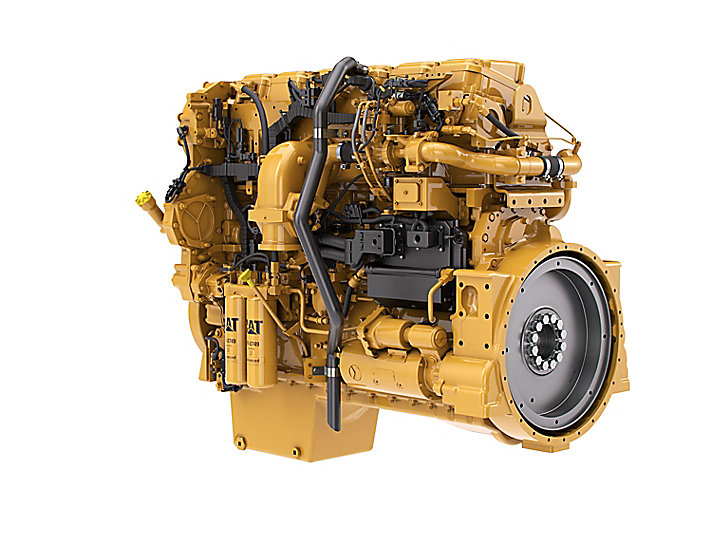

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Caterpillar C11, C13, C15, C18. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your engine like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

Caterpillar Generator Manuals. CATERPILLER 3508 DIESEL ENGINE SERVICE MANUAL PDF DOWNLOAD; Caterpillar GEP33-3 operator and maintenance manual. Cat RP12000 E: 'This is one heavy-duty portable generator.' — HouseholdMe 'This is one heavy-duty portable generator. The Cat RP12000E Gas Powered Portable Generator 502-3699 is user-friendly and safe enough to use for household electricity needs yet tough and powerful enough to withstand rough handling on job sites.

This manual for Caterpillar C11, C13, C15, C18 is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

MAKE: Caterpillar

MODEL: C11, C13, C15, C18 Engine

FORMAT: PDF

ENGINE – INDUSTRIAL

Model Prefix

C11 INDUSTRIAL ENGINE GLS

C11 INDUSTRIAL ENGINE HRA

ENGINE – MACHINE

Model Prefix

C11 ENGINE – MACHINE RSX

C11 ENGINE – MACHINE TXE

ENGINE – TRUCK

Model Prefix

C11 TRUCK ENGINE KCA

PETROLEUM PRODUCTS

Model Prefix

C11 PETROLEUM ENGINE B5K

C11 PETROLEUM ENGINE B5Z

ENGINE – GENERATOR SET

Model Prefix

C13 GENERATOR SET DH4

C13 GENERATOR SET NH3

C13 GENERATOR SET NH4

C13 XQ350 GENERATOR SET X3M

ENGINE – INDUSTRIAL

Model Prefix

C13 INDUSTRIAL ENGINE KWJ

C13 INDUSTRIAL ENGINE LGK

C13 INDUSTRIAL ENGINE N3F

C13 INDUSTRIAL ENGINE RRA

ENGINE – MACHINE

Model Prefix

C-13 ENGINE – MACHINE MHX

C13 ENGINE – MACHINE M4L

C13 ENGINE – MACHINE M4X

C13 ENGINE – MACHINE MHX

C13 ENGINE – MACHINE T4F

C13 ENGINE – MACHINE TXF

C13 ENGINE – MACHINE TXM

C13 ENGINE – MACHINE TXX

ENGINE – TRUCK

Model Prefix

C13 TRUCK ENGINE EMS

C13 TRUCK ENGINE JAM

C13 TRUCK ENGINE KCB

C13 TRUCK ENGINE LEE

C13 TRUCK ENGINE PRM

C13 TRUCK ENGINE S3C

PETROLEUM PRODUCTS

Model Prefix

C13 PETROLEUM ENGINE A5K

C13 PETROLEUM ENGINE A5Z

ENGINE – GENERATOR SET

Model Prefix

C15 GENERATOR SET C5E

C15 GENERATOR SET C5H

C15 GENERATOR SET C5L

C15 GENERATOR SET CYY

C15 GENERATOR SET GB3

C15 GENERATOR SET L8B

C15 GENERATOR SET LNA

C15 GENERATOR SET LXJ

C15 GENERATOR SET LZA

C15 GENERATOR SET MBS

C15 GENERATOR SET NKL

C15 GENERATOR SET PEC

C15 GENERATOR SET SNW

C15 GENERATOR SET STG

C15 GENERATOR SET T4A

C15 GENERATOR SET X4R

C15 GENERATOR SET X5M

C15 GENERATOR SET ZKA

C15 I6 GENERATOR SET NAP

ENGINE – INDUSTRIAL

Model Prefix

C-15 INDUSTRIAL ENGINE BEM

C15 INDUSTRIAL ENGINE JAS

C15 INDUSTRIAL ENGINE JKG

C15 INDUSTRIAL ENGINE JRE

C15 INDUSTRIAL ENGINE LDN

C15 INDUSTRIAL ENGINE MCW

C15 INDUSTRIAL ENGINE N5F

ENGINE – MACHINE

Model Prefix

C-15 ENGINE – MACHINE A3A

C15 ENGINE – MACHINE ENG

C15 ENGINE – MACHINE L4L

C15 ENGINE – MACHINE L4X

C15 ENGINE – MACHINE LHX

C15 ENGINE – MACHINE TXG

C15 ENGINE – MACHINE TXL

C15 ENGINE – MACHINE TXY

ENGINE – TRUCK

Model Prefix

C-15 REMAN ENGINE C2A

C-15 TRUCK ENGINE 6NZ

C-15 TRUCK ENGINE 9NZ

C-15 TRUCK ENGINE EGH

C-15 TRUCK ENGINE MBN

C15 TRUCK ENGINE B5R

C15 TRUCK ENGINE BXS

C15 TRUCK ENGINE JEP

C15 TRUCK ENGINE KRA

C15 TRUCK ENGINE MHP

C15 TRUCK ENGINE MXS

C15 TRUCK ENGINE NXS

C15 TRUCK ENGINE RKS

C15 TRUCK ENGINE SDP

C15 TRUCK ENGINE TRB

MARINE PRODUCTS

Model Prefix

C15 MARINE ENGINE RLA

PETROLEUM PRODUCTS

Model Prefix

C-15 PETROLEUM ENGINE Z2C

C15 PETROLEUM ENGINE HAZ

C15 PETROLEUM ENGINE JDK

C15 PETROLEUM ENGINE JDY

C15 PETROLEUM ENGINE MG2

C15 PETROLEUM ENGINE SWE

C15 PETROLEUM GEN SET 115

C15 PETROLEUM GEN SET LWR

C15 PETROLEUM GEN SET PET

ENGINE – GENERATOR SET

Model Prefix

C18 GENERATOR SET C6C

C18 GENERATOR SET CYL

C18 GENERATOR SET DDS

C18 GENERATOR SET DKE

C18 GENERATOR SET EKW

C18 GENERATOR SET G4C

C18 GENERATOR SET L8D

C18 GENERATOR SET LNB

C18 GENERATOR SET LXK

C18 GENERATOR SET LZB

C18 GENERATOR SET M1P

C18 GENERATOR SET M1Y

C18 GENERATOR SET M1Z

C18 GENERATOR SET N1C

C18 GENERATOR SET N1D

C18 GENERATOR SET NKK

C18 GENERATOR SET PEE

C18 GENERATOR SET PEJ

C18 GENERATOR SET STD

C18 GENERATOR SET STM

C18 POWER MODULE X6X

C18 I6 GENERATOR SET NAW

ENGINE – INDUSTRIAL

Model Prefix

C18 INDUSTRIAL ENGINE BDN

C18 INDUSTRIAL ENGINE EJG

C18 INDUSTRIAL ENGINE GJE

C18 INDUSTRIAL ENGINE JDA

C18 INDUSTRIAL ENGINE N8F

C18 INDUSTRIAL ENGINE NBB

C18 INDUSTRIAL ENGINE WJB

C18 INDUSTRIAL ENGINE WJH

C18 INDUSTRIAL ENGINE WRH

C18 INDUSTRIAL ENGINE ZPS

ENGINE – MACHINE

Model Prefix

C18 ENGINE – MACHINE R4L

C18 ENGINE – MACHINE RDP

C18 ENGINE – MACHINE RHX

C18 ENGINE – MACHINE TXH

C18 ENGINE – MACHINE TXW

ENGINE – TRUCK

Model Prefix

C-18 TRUCK ENGINE MDP

C-18 TRUCK ENGINE MEP

C18 TRUCK ENGINE CJP

ENGINEER SUPPORT TRACTOR

Model Prefix

C18 GENERATOR SET EKW

MARINE PRODUCTS

Model Prefix

C18 GENERATOR SET DTP

C18 GENERATOR SET GBM

C18 GENERATOR SET JHL

C18 GENERATOR SET MGS

C18 MARINE ENGINE C1J

C18 MARINE ENGINE CKH

C18 MARINE ENGINE CYN

C18 MARINE ENGINE GEN

C18 MARINE ENGINE GES

C18 MARINE ENGINE GEX

C18 MARINE ENGINE GTB

C18 MARINE ENGINE J2K

C18 MARINE ENGINE JKX

C18 MARINE ENGINE JLE

C18 MARINE ENGINE KJT

C18 MARINE ENGINE NAX

C18 MARINE ENGINE NAY

C18 MARINE ENGINE PLE

C18 MARINE ENGINE T2P

C18 MARINE ENGINE T2R

C18 MARINE ENGINE TNA

C18 MARINE ENGINE WKB

PETROLEUM PRODUCTS

Model Prefix

C18 PETROLEUM ENGINE BE2

C18 PETROLEUM ENGINE WJW

C18 PETROLEUM ENGINE WJY

C18 PETROLEUM GEN SET 188

Cat 3604 Generator Manual Generator

SERR9700 – Service Manual (C11 & C13 & C15 & C16 & C18 ACERT On-highway Engines)

BatteryCrossRef.pdf

BatterySpecs.pdf

C13 PARTS MANUAL.pdf

Disassembly and Assembly c15 c16 c18.pdf

DSTC.pdf

mainmenu.pdf

oss.pdf

REHS1413-04-01-ALL.pdf

RENR1282-11-01-ALL.pdf

SEBU7695-06-01-ALL.pdf

SENR2995-04-01-ALL.pdf

SENR3130-10-01-ALL.pdf

SENR9698-09-01-ALL.pdf

SENR9701-03-01-ALL.pdf

SENR9702-05-02-ALL.pdf

SENR9703-05-01-ALL.pdf

SENR9704-05-01-ALL.pdf

SENR9705-02-01-ALL.pdf

SERP3815-31-01-ALL.pdf

ShopSupplies&Tools.pdf

Specification C-15.pdf

…

EXCERPT:

Testing and Adjusting

C11 and C13 On-Highway Engines

Vibration Damper – Check

Rubber Vibration Damper (If Equipped)

View Image

Illustration 1

Vibration damper and pulley

(1) Adapter

(2) Rubber

(3) Damper assembly

(4) Bolt

(5) Crankshaft pulley

The vibration damper is installed on the front of crankshaft. The space in the damper assembly (3) is filled with rubber (2) . The vibration damper limits the torsional vibration.

Replace the damper if any of the following conditions exist:

The damper is dented or cracked. Insta 360 studio lagging.

The paint on the damper is discolored from heat.

There is a large amount of gear train wear that is not caused by lack of oil.

Analysis of the oil has revealed that the front main bearing is badly worn.

The engine has had a failure because of a broken crankshaft.

Viscous Vibration Damper (If Equipped)

View Image

Illustration 2 g01363868

Viscous vibration damper

(6) Pulley

(7) Weight

(8) Case

Damage to the vibration damper or failure of the vibration damper will increase vibrations. This will result in damage to the crankshaft.

Replace the damper if any of the following conditions exist:

The damper is dented, cracked, or fluid is leaking from the damper.

The paint on the damper is discolored from excessive heat.

The damper is bent.

The bolt holes are worn or there is a loose fit for the bolts.

The engine has had a crankshaft failure due to torsional forces.

NOTICE

Inspect the viscous vibration damper for signs of leaking and for signs of damage to the case. Either of these conditions can cause the weight to contact the case. This contact can affect damper operation.

CATERPILLAR SERVICE MANUALS

Everybody knows that Caterpillar produces the finest machinery in the world! But even the finest piece of equipment will need service, repair, and regular maintenance. A factory Caterpillar service manual is the only real choice. The free Caterpillar operators manual is helpful for becoming familiar with the operation and minor maintenance of your Caterpillar. But, an authentic Caterpillar service manual PDF is a must-have item for both the professional and the do-it-yourself mechanic. You already know this if you are the person responsible for repairing Caterpillar equipment for a shop, farm, or construction site.

CAT TECHNICAL PUBLICATION MANUALS

These Caterpillar service manuals provide detailed instruction on the major repair components of your Caterpillar equipment. We carry only the Caterpillar Original Equipment Manufacturers (OEM) manuals. CAT factory service repair manuals are far superior to generic aftermarket repair manuals. Illustrated diagrams are included in the Caterpillar service manuals.Diagnostic, testing, adjustment, theory of operation, and repair information is all prided in the CAT full service manual PDF.

CATERPILLAR SERVICE MANUAL DOWNLOAD

The Caterpillar Manuals we have available online here are the finest standard reference for all Caterpillar repairs. The Caterpillar Technical Service Manual is an extremely clear and highly detailed manual, originally designed for the Shop Mechanics at the Caterpillar dealer. With every repair manual containing between 500 an 900 pages, it only makes sense that this authentic Caterpillar factory Service Manual PDF will pay for itself several times over the very first time you even look at it. Most Internet websites and Technical Service Publications refer to these exact service manuals when answering technical questions in forums and articles. Every conceivable technical “how to” question is answered and explained. It is the finest and most up-to-date Caterpillar workshop manual reference available. This Caterpillar Service Manual is a “must have” for every CAT.

INSTANT DOWNLOAD AN EASY TO READ CATERPILLAR MANUAL PDF FILE

Fully BOOKMARKED chapters for easy navigation allowing you to identify the exact service repair procedures in the quickest time possible.

Completely SEARCHABLE – so you can easily find what you are looking for.

Detailed illustrations, exploded diagrams, drawings and photos guide you through every service repair procedure.

This Caterpillar Service Manual is compatible with all PC and Mac systems and is also easy to use on any tablet or smartphone, such as Android, iPhone, and iPad.

Would you like to see the quality of an online Caterpillar Service Manual? We have a free sample available online for download! CLICK HEREto download a sample Caterpillar manual. The free sample is just the free operation and maintenance manual for you to see how easy it is to download. When you pay, you will get the much more detailed factory service repair manual. At least the free sample allows you to see how easily it can be viewed on any computer, as well as zoomed and printed. You can print out the entire manual, or most mechanics like to print out just the sections they need at the moment. The paper will probably get ruined anyway, so just throw it away when your work is complete! Search for your specific Caterpillar Service Manual now by typing in the model in the search box at the top of the page. It’s really that easy!

SOME OF THE NOTABLE ACHIEVEMENTS WITH THE HELP OF A CAT REPAIR MANUAL

2002 – U.S.

Nearly 220 Caterpillar machines benefited from the CAT manual PDF to help build a natural gas pipeline from Wyoming to Southern California.

2002 – South Korea and Japan

Caterpillar generator set manuals provided uninterrupted power for the 2002 World Cup soccer match for the duration of the event.

2002-2006 – Iceland

More than 100 Cat machines help build the Karahnjukar Hydropower Project under construction in Iceland and received professional repairs from the Caterpillar workshop manual.

2003 – Paris, France

More than 600 Caterpillar machines help construct additional lines for the Ligne a Grande Vitesse.

Between 1977 and 1983, more than 200 Cat machines worked on the first lines for the new Ligne a Grande Vitesse (high speed train) constructed between Paris and Lyon. From 1987-1989, more than 80 Cat machines were involved in constructing an additional 160-mile rail line from Paris to LeMans, along with its 300 overpasses and 21 tunnels. In 2003, Cat machines once again played a role in the construction of France’s high-speed rail network when contractors used the Cat online service manual to repair more than 600 Cat machines.

2003 – U.S.

Caterpillar provides the majority of power generation and dealer support during the largest power outage in U.S. history (to this date).

More than 300 backup generators and two megawatt trailer units were trucked to cities such as New York, Cleveland and Detroit to get them up and running again. Trading on Wall Street was uninterrupted thanks to Cat power service repair workshop manual.

2003-2010 – Arizona & Nevada

Caterpillar machines help construct a bypass highway near the Hoover Dam to replace the original highway that runs over the dam.

2004 – Indian Ocean Tsunami

Caterpillar machines and dealer personnel assist with cleanup and relief efforts after the earthquake and tsunami that devastated the Asia-Pacific region.

2004-2010 – Shanghai, China

Caterpillar machines help build the infrastructure Shanghai needs to host the 2010 World’s Fair and Exposition.

2004-2014 – Romania

Cat machines help construct the 588-kilometer-long Transylvania Motorway.

When complete, the Transylvania Motorway will connect Bucharest with Oradea. Contractors used the Cat manual PDF download to construct just one 258-mile segment of the four-lane highway that featured over 300 bridges, 70 overpasses and 19 interchanges.

2005 – U.S.

Caterpillar and its dealer network respond with people, products, and financial aid to help with recovery efforts in the Gulf Coast following Hurricanes Katrina, Rita and Wilma.

2005 – Alberta, Canada

Continuing work begun in 1967, Caterpillar machines are still working in the Athabasca Oil Sands.

At this point in time, there are around 500 pieces of Caterpillar equipment belonging to 20 different companies working in the oil sands. The world’s largest fleet of 797 mining trucks (100 total) is working around the clock hauling oil sand to facilities for processing.

Featured by terratec promedia driver. 2005 – India

A fleet of 220 Caterpillar machines and gen sets works on the 3,625 miles of a four-to-six lane highway known as the Golden Quadrilateral.

2006 – U.S.

Caterpillar machines play a major part in the construction of the 300-mile-long Entrega Pipeline.

The Entrega Pipeline was the first stage of the Rockies Express Pipeline. Stretching from Wyoming to Ohio, the 1,663-mile Rockies Express Pipeline will connect Rocky Mountain natural gas reserves to consumers on the East Coast. The online Caterpillar PDF manual download goes beyond construction equipment. Solar gas turbines, Gas Caterpillar Motoren (GCM) compression engines (Entrega is the first new mainline pipeline to use GCM engines), Cat Financial services and 6 Sigma-enhanced strategic support planning were key elements of the project. The completed pipeline will utilize the Caterpillar full service repair manual download solution enabling real-time monitoring and predictive maintenance to maximize performance and minimize costs.

Cat 3604 Generator Manual Pdf

2006 – South Korea

Thirty-four Caterpillar machines help complete the Saemangeum Seawall – the world’s longest earthen seawall.

2007 – Russia

Cat machines help construct the 1,100-kilometer Yamal-Ukhata pipeline.

Russia’s Yamal-Ukhta pipeline is part of a planned 2,500-kilometer gas transportation system built in one of the world’s most extreme climates thanks in part to the instruction and guidance of the Caterpillar Repair manual download.

2007-2014 – Panama

Cat machines help construct the expansion of the Panama Canal.

Contractors used 75 Cat machines on just the first two phases of the six-phase project. When complete, the new single-lane, three-step lock system will allow the Panama Canal to accommodate vessels that are not currently transiting the waterway due to their large size.

2008-2011 – Saudi Arabia

Over 400 new Caterpillar machines still need repair from the CAT manual PDF to help construct a 2,400-kilometer rail line through the Nafud Desert in Saudi Arabia.